INDUSTRIES SERVED

- The major services offering by TRIDENT WELDING RESEARCH & ACADEMY (TWRA) to the industrial sector includes: Research and Development in establishment and application of various welding processes catering to the appropriate needs of industries, serving varied sectors. It is indulged in carrying out metallurgical investigations including Failure Analysis, and remnant life assessment.

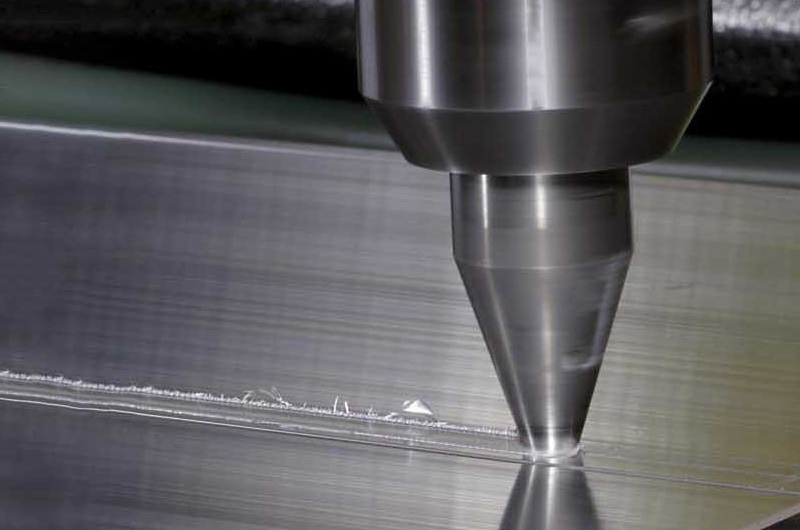

FRICTION STIR WELDING

Friction stir welding is a solid-state joining process that uses a non-consumable tool to join two facing workpieces without melting the workpiece material. Heat is generated by friction between the rotating tool and the workpiece material, which leads to a softened region near the FSW tool.

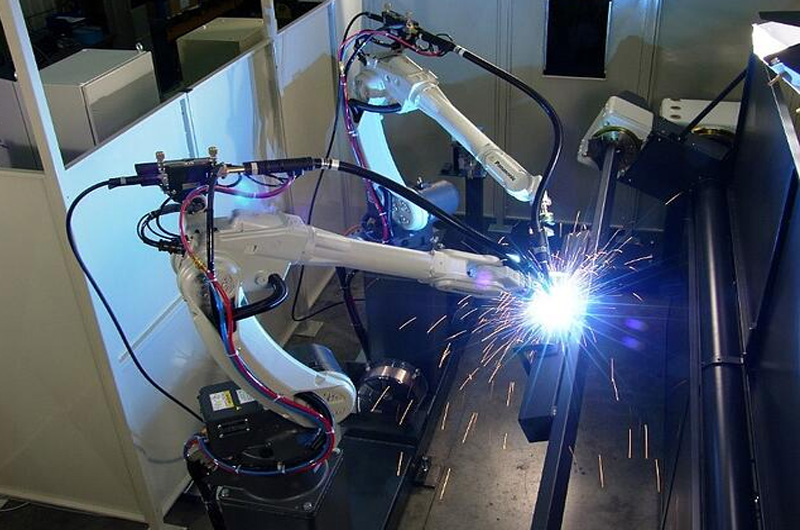

GTAW & GMAW processes

Gas Tungsten Arc Welding (GTAW) GMAW utilizes a consumable electrode. So electrode material melts down and deposits on weld bead. GTAW or TIG welding uses non-consumable electrode and thus electrode material is not deposited on weld bead.

Technology Development

TWRA is providing Technology Development Mechanisation & automation, joining methods for all types of similar & dissimilar materials and introduction of new processes & techniques

Welding Procedure Specification

Assessment of weldability of new materials establishment of welding procedures as per pressure vessel, structural welding or applicable codes and evolve Welding Procedure Specification.

Testing and Inspection Services

Mechanical, Chemical and Non Destructive Testing of weld joints, testing and evaluation of Welding Consumables & Power Sources.

TWRA service

The expertise of TWRA is proved by its holistic consultancy services and solutions to industrial problems through long term MOUs and one-time contracts.